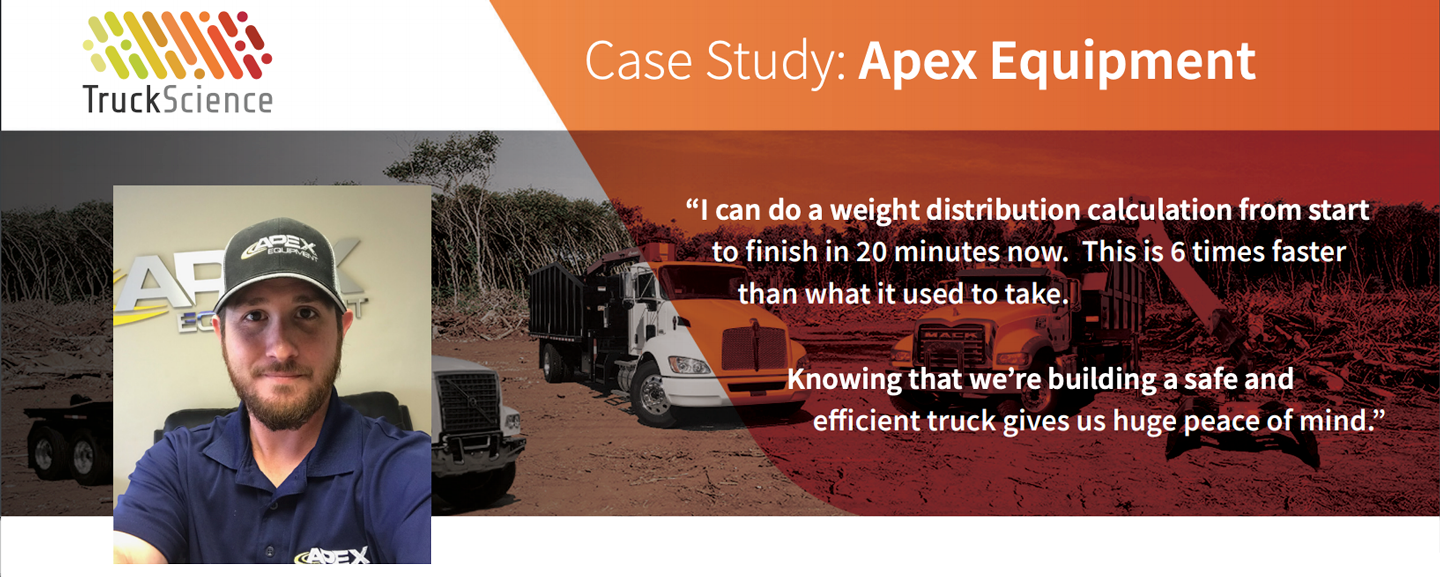

Tim Gandolfo

Director of Operations, Apex Equipment Sales, Inc., Florida, USA

Before TruckScience

Before trying the TruckScience Axle Weight Calculator, Tim had been using NTEA’s basic WT&CG Spreadsheet and ULTRAMOD. He was looking for built-in validation to flag potential errors, and a graphical epresentation of the build to easily detect mistakes.

Implementing TruckScience

“We implemented the TruckScience Axle Weight Calculator in August 2019, in response to NTEA’s recommendation. I found it really easy to get started with the tool.

The library of vehicles means that 95% of the work is done before I start a calculation. I open a template for the vehicle I’m working on, use the IVD to customize the truck, and can quickly see if what I’ve configured looks right.”

Impact of TruckScience

“The graphical representation is a gamechanger, allowing me to perform sanity checks as I go.

We can take a product that we have in mind. Instead of seeing it in numbers, we can see what it will actually look like.

We can put a really professional proposal on paper within minutes, and we can foresee issues before we run into them on the ground.

All of our customers love it. It helps them to understand what they can and can’t do, and some even use our reports in driver training.”

Favorite Feature

“I used to have to test different payload figures for Grapple Trucks, to see what would push my GVW over the limit. With the TruckScience app, the maximum achievable payload is based off the Bridge Formula and the GVWR, and is automatically recalculated on the fly. Every change that I make is immediately reflected in the payload.

Having my work checked by the built-in validation in the program gives me great peace of mind”